Optics manufacturing

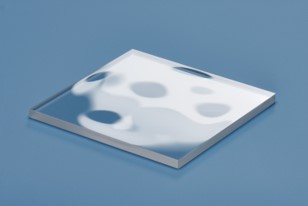

Trionplas Technologies GmbH offers the production of individual, highly precise optical elements with a multitude of design possibilities, like apheric, acylindric and free-form optics.

Plasma jet technology

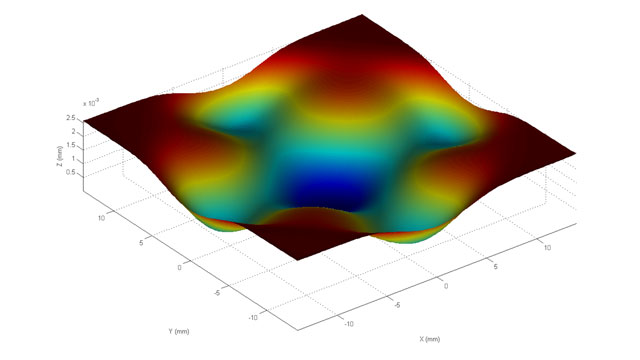

We produce highly precise, individually designed optical elements. We can supply any number of optical elements, from single pieces to a serial production of multiple pieces. We use an innovative technology for surface modification – called plasma jet technology. This atmospheric shaping process is based on the local, chemical ablation of material with the help of reactive gas, which is produced by microwave excited plasma sources. Because we use very small tool functionalities and computer driven time retention processes, we can produce nearly any optical designs imaginable.

The way to free-form optics

Please supply us with your desired design, either as a mathematical function or an XYZ topography. Let us know which material you prefer (fused silica, silicon, silicon carbid, germanium) and which size (diameter up to about 200 mm) as well as the preferred precision. Precision is defined by the deviation from the norm in RMSi.

We offer 4 accuracy classes

| level of precision | residual error RMSi |

|---|---|

| Low | < 1000nm |

| Standard | < 250nm |

| High | <100nm |

| Ultra | <25nm |

Please send inquiries to:

Trionplas Technologies GmbH

Permoserstr. 15

D-04318 Leipzig

Germany

Email: info@trionplas.de

Optics Correction

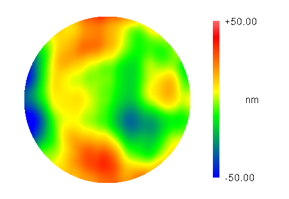

We modify your optical element with regard to form and precision, offering correction and revision of surface defects such as scratches or point defects.

Optics Correction

We modify your optical element with regard to form and precision, offering correction and revision of surface defects such as scratches or point defects.

Measurement

We employ optical and tactile surveying systems for operational test measurement and characterisation of optical elements and surfaces, measuring form and abrasiveness.

We have a wide range of techniques available including interferometric scanning, laser profiling, white light interferometry as well as contact sensitive, tactile measurement techniques.

Calibration standards

We offer abrasiveness and resolution standards for the calibration and examination of optical and tactile measuring systems – individually produced.

Please send inquiries to:

Trionplas Technologies GmbH

Permoserstr. 15

D-04318 Leipzig

Germany

Email: info@trionplas.de